Hot-melt Adhesive for Automotive Light WD8560B

WD8560B is a single component reactive polyurethane hot melt adhesive, which is a solid at room temperature, becomes a liquid after heating, and forms a preliminary bond after coating and bonding. It then has excellent adhesion, temperature resistance, water resistance, oil resistance, and aging resistance due to its ability to cure with air and moisture on the surface of the bonded material.

This product complies with the standards specified in GB33372-2020 Limits of Volatile Organic Compounds in Adhesives.

Applied in automotive interiors and traffic lights, it has good bonding properties to materials such as PVC, ABS, PMMA, PP, etc. after corona treatment.

1.Single component, easy to manage, suitable for mechanized operation, high efficiency.

2.Solid content of 100%, no pollution, environmentally friendly.

3.Short opening time and fast positioning speed.

1.The bonding surface must be kept dry, clean, and free of oil stains, and should be appropriately polished.

2.For low polarity materials such as PP, corona/flame treatment is required to ensure a dielectric constant of 34 or higher.

3.During use, the surface temperature of the adhered material should not be lower than 20 ℃. If it is necessary to bond the material, it needs to be heated.

4.Use a sealed PUR glue system for glue melting, please use the melted glue as soon as possible.

5.Using a dedicated PUR adhesive system, adhesive is applied through rolling, scraping, spraying, and other methods.

6.Molten glue and glue that leaks in the air should be used up within 2-3 hours as much as possible.

7.The optimal curing environment conditions are a temperature of 25 ℃ and a humidity of 50% or above.

8.Use PUR specific cleaning agent for cleaning.

1.Local exhaust devices should be installed in the operating area to ensure ventilation.

2.When using, it is necessary to wear work clothes, cotton gloves, protective masks, goggles and other personal protective equipment.

3.The product may solidify due to moisture, so the packaging sealing should be carefully checked before use to ensure that the product is sealed properly.

4.Do not mix the product with other grades of hot melt adhesive.

5.Please read the product safety manual carefully before use.

Performance indicators

|

Project |

Standard |

Test method |

|

|

Material |

Polyurethane |

||

|

Appearance |

Melt temperature |

Black viscous liquid |

visualization |

|

Room temperature |

Black solid |

visualization |

|

|

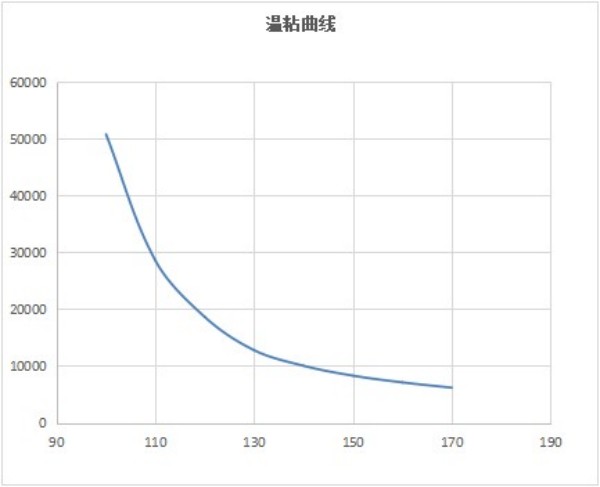

Viscosity/mPa · S |

120℃ |

10000~50000 |

HG/T 3660-1999 |

|

140℃ |

5000~25000 |

HG/T 3660-1999 |

|

|

Stability/mPa · S (120 ℃&12h) |

120℃ |

≤100000 |

GB/T16998-1997 |

|

140℃ |

≤50000 |

GB/T16998-1998 |

|

|

Specific gravity/g/cm3 |

1.00~1.10 |

GB/T 13354 |

|

Operating conditions

|

Project |

Standard |

|

Opening time/(min/5mm) |

≤10 |

|

Positioning time/(min/5mm) |

≤30 |

|

Melt glue temperature/℃ |

120~150 |

|

Glue application temperature/℃ |

120~150 |

Melt viscosity - temperature curve

Aluminum foil bag/drum composite sealed packaging: 200kg/drum, 25kg/drum, 20kg/drum or customer requirements

Storage environment: Store in a cool and dry room at 5-35 ℃.

Storage period in the original sealed container: 9 months.