Hot-melt Adhesive for Textile Lamination WD8502

WD8502 is a single component, solvent-free, moisture curing reactive polyurethane hot melt adhesive. It has excellent adhesion, temperature resistance, and water resistance.

WD8502 is mainly suitable for bonding functional fabrics with materials such as TPU film, PU film, and TPEF film.

1.Single component, suitable for mechanized operation, high production efficiency.

2.Solid content of 100%, environmentally friendly.

3.Good initial adhesion and conducive to processing.

4.Excellent flexibility and moisture permeability.

Performance indicators

|

Project |

Standard |

Test method |

|

|

Material |

Polyurethane |

||

|

Appearance |

Melt temperature |

Colorless to pale yellow transparent liquid |

visualization |

|

Room temperature |

White to pale yellow solid |

visualization |

|

|

Viscosity/mPa · S |

90℃ |

3000~4000 |

HG/T 3660-1999 |

|

Specific gravity/g/cm3 |

1.20±0.1 |

GB/T 13354 |

|

|

Melt glue temperature/℃ |

90~110 |

- |

|

|

Glue application temperature/℃ |

80~95 |

- |

|

|

Coating amount/g/m2 |

8~20 |

According to application conditions |

|

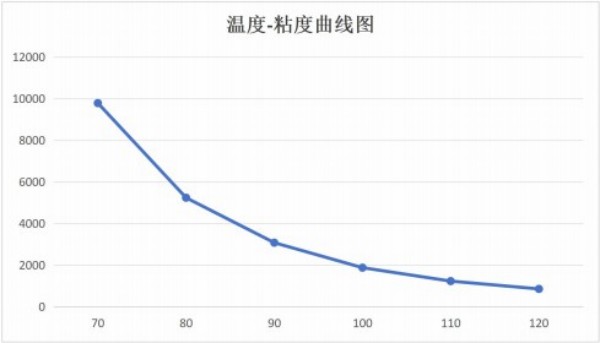

Melt viscosity - temperature curve

|

Temperature/℃ |

70 |

80 |

90 |

100 |

110 |

120 |

|

Viscosity/mPa · S |

9780 |

5235 |

3075 |

1875 |

1230 |

855 |

Preprocessing

1.Clean up the oil stains and dust on the bonding surface.

2.For materials with surface energy below 32 dynes, corona or flame treatment is required to ensure a dyne value of 36 or above.

3.The surface temperature of the adhered object cannot be lower than 20 ℃. If the temperature is too low, the opening time will be shortened to reduce the operating time, which may result in poor adhesion.

Coating method

1.Use a closed melt adhesive system for melt adhesive. If any abnormal phenomena such as increased viscosity, particles, or foaming are found during the melt adhesive process, please contact the technical sales personnel immediately.

2.The coating method includes rolling, scraping, and spraying.

Curing time

The bonded product should be stored at an appropriate temperature or humidity (temperature>20 ℃, humidity>50%), and after curing for 1-2 days, it should reach a strength of over 90%.

Cleaning method

1.Melt glue system: Special cleaning agent WD8600 is used for rinsing.

2.Glue application system: The scraper and roller are rinsed with specialized cleaning agent WD8602.

This product can react with water vapor in the air, causing an increase in viscosity and failure. Therefore, please carefully check the sealing of the packaging before use. Only when the seal is intact can it be used. After opening, use up as soon as possible. The workplace must ensure ventilation. Operators are required to wear work clothes, cotton gloves, protective masks, goggles, and other personal protective equipment. Please read the product safety manual carefully before use.

Environmental temperature: Store in a cool and dry room at 5-38 ℃.

Storage period in the original sealed container: 9 months.

Aluminum foil bag/drum composite sealed packaging: 20kg/drum or 200kg/drum.