PriceList for Polyurethane Adhesive For Wind Blade – Wind Turbine Blade Polyurethane Infusion Resin WD8085A/WD8085B / Wind Power Blade Epoxy Matrix Resin WD0135/WD0137 – KANGDA

PriceList for Polyurethane Adhesive For Wind Blade – Wind Turbine Blade Polyurethane Infusion Resin WD8085A/WD8085B / Wind Power Blade Epoxy Matrix Resin WD0135/WD0137 – KANGDA Detail:

Wind Turbine Blade Polyurethane Infusion Resin WD8085A/WD8085B

WD8085A/B is specially developed for the vacuum infusion process of wind turbine blades. It has low viscosity at room temperature, long operation time, fast curing after heating, and high production efficiency. It has excellent mechanical properties, excellent impact resistance, fatigue resistance and chemical corrosion resistance.

Wind Power Blade Epoxy Matrix Resin WD0135/WD0137

The main agent WD0135 and curing agent WD0137 are two components of the solvent-free epoxy resin system. After mixture, the resin system exhibits low viscosity, long operating time, and after being cured, it exhibits high strength, high toughness, low density, low shrinkage and other properties. Therefore, the WD0135/WD0137 epoxy resin system is especially suitable for vacuum infusion to wind turbine blades .

The WD0135/WD0137 resin system has low mixing viscosity, excellent wetting property to glass fiber, and the system does not contain any volatile substances, suitable for RTM vacuum infusion craft, mainly used in the manufacture of wind turbine blades.

| Wind Turbine Blade Polyurethane Infusion Resin WD8085A/WD8085B | Wind Power Blade Epoxy Matrix Resin WD0135/WD0137 |

| Low viscosity, Long operation time, good wettability | Accredited by GL; |

| Fast curing speed, shorten molding time | low viscosity, excellent wettability; |

| Special formula design reduces sensitivity to moisture | Excellent physical and mechanical performance and excellent fatigue resistance. |

| Excellent physical and mechanical properties and fatigue resistance |

Applicable to vacuum filling process of wind turbine blade; Applicable to preparation of glass fiber composites.

Teach you how to choose a reliable wind turbine blade adhesive:

A) With high strength and toughness, must be able to withstand the centrifugal force of each blade;

B) Excellent operating characteristics, such as no slump, easy pumping, etc.;

C) Good wetting and thixotropy;

D) High compressive resistance, fatigue resistance and aging resistance;

E) The reaction cycle of the adhesive should be closely consistent with the working cycle of the blade die;

F) Excellent gap filling ability, suitable for adhesive tape of different thickness;

G) Low heat release and low curing shrinkage.

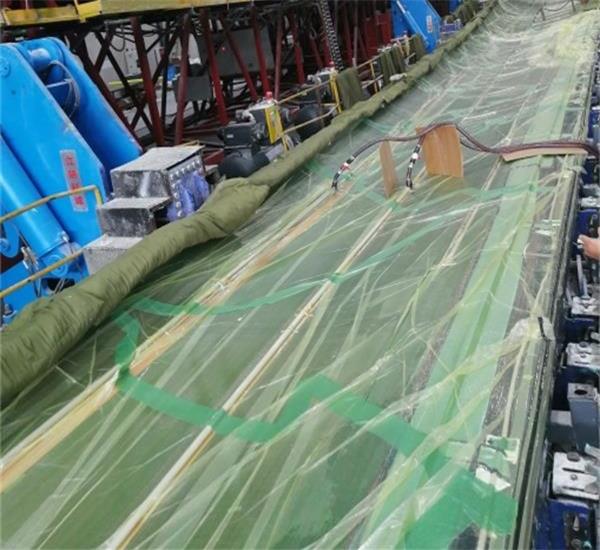

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for PriceList for Polyurethane Adhesive For Wind Blade – Wind Turbine Blade Polyurethane Infusion Resin WD8085A/WD8085B / Wind Power Blade Epoxy Matrix Resin WD0135/WD0137 – KANGDA , The product will supply to all over the world, such as: Indonesia, Zurich, Slovakia, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.